Locking up carbon for good: Easthampton inventor’s CO2 removal system turns biomass into biochar

|

Published: 04-24-2024 4:44 PM

Modified: 04-25-2024 4:54 PM |

HOLYOKE — Like many people, Michael Garjian believes global warming is a pressing issue of our times.

Unlike most, he’s putting his ideas for reducing carbon dioxide in the atmosphere into practice — and at the same time bidding for a share of the $100 million XPrize for Carbon Removal funded by Elon Musk.

Garjian, 77, of Easthampton, is an inventor who has 10 or 11 patents to his name. Many years back, he followed up his flat, energy-efficient lighting panels with artistic designs in neon that attracted Japanese investors and led him to open a factory in Chicopee. He had to close it down after Japan’s economic collapse in the 1990s.

After working on small business start-ups with Valley Community Development, he and his wife, Irene, got interested in biochar, the carbon-rich residue derived from the pyrolysis — thermal decomposition under oxygen-limited conditions — of biomass. The two of them formed the company CarbonStar Systems.

Now, with the XPrize announcing Garjian’s project on a list of 100 honorees out of more than 1,400 entries, he’s ready to unveil the CarbonStar Catalytic Pyrolysis System, a computer-controlled apparatus that turns biomass — wood chips, seaweed, canola meal — into biochar and a lot more besides.

“This is a mobile system,” Garjian said Tuesday in the factory space where it was built. “It can produce energy, heat, light anywhere on the planet there’s feedstock.”

Garjian’s interest in a land-based approach to carbon capture was spurred by the carbon cycle of trees and crops. While living trees absorb CO2, they release it all when they die and decompose.

“Dead, decaying biomass puts out more CO2 than all human activity,” he said.

Article continues after...

Yesterday's Most Read Articles

A Waterfront revival: Two years after buying closed tavern, Holyoke couple set to open new event venue

A Waterfront revival: Two years after buying closed tavern, Holyoke couple set to open new event venue

3-unit, 10-bed house in backyard called too much for Amherst historic district

3-unit, 10-bed house in backyard called too much for Amherst historic district

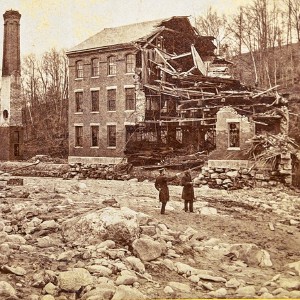

The long shadow of the Mill River flood: Multiple events on tap in May to mark 150th anniversary of the 1874 disaster

The long shadow of the Mill River flood: Multiple events on tap in May to mark 150th anniversary of the 1874 disaster

ValleyBike to roll again by end of May in eight communities throughout Valley

ValleyBike to roll again by end of May in eight communities throughout Valley

Amherst College store opens downtown in former Hastings space

Amherst College store opens downtown in former Hastings space

Area property deed transfers, May 2

Area property deed transfers, May 2

Last year’s forest fires in Canada emitted a billion tons of CO2 between May and June alone, he said.

Turning dead wood or other biomass material into biochar is a way to stop it from producing methane, he said.

The physics of carbon capture is complex, as is measuring the weight of CO2. Garjian said his process results in a measurable carbon capture because the biochar it produces is 70-90% pure elemental carbon that would otherwise have been released as carbon dioxide by the fuel being burned or decomposing.

The system sends the wood chips through a vacuum tube where heat bands remove the moisture, leaving a charcoal-like substance. Liquids and gases are separated out and the end result is biochar. The vacuum means no combustion is used in the process.

Garjian is an advocate for the multiple benefits of biochar. He said it has an electrical charge and can revive depleted soil and filter wastewater. It can be used as an additive in concrete to reduce its CO2 emissions, and can neutralize “forever chemicals.”

He noted that Sublime Systems is in the process of constructing a low-carbon cement plant in Holyoke, and he hopes they will be interested in some sort of partnership.

The remainder of the CarbonStar system separates emitted hydrocarbon vapors into heavy and light bio-oils, with the gases diverted to produce the power to operate the system and the remaining liquid forming wood vinegar, used as plant food and for pest control.

Bio-oils can be used as heating oil or be refined to produce automotive and aviation fuels.

The computer controlling the process gives a read-out from 34 sensors monitoring temperature, pressure and other variables throughout the system.

“It’s the most advanced pyrolysis system in the world,” Garjian said.

Recognition from the XPrize judging panel has been “great validation,” he said, but he’s aiming to go into production with his machine regardless of how it fares further in the competition. Fifteen projects were awarded $1 million each in April 2022, so-called milestone awards. Of the remaining $85 million, $50 million will be awarded to the grand prize winner next April, while $30 million will be shared by up to three runners-up. Additionally, 23 student teams shared $5 million in prizes awarded in November 2021.

On Wednesday, XPrize announced that CarbonStar Systems was one of 39 companies in the Land category of the top 100, 28 of which involve biochar. The remaining 61 finalists are in three other categories — Air, Ocean and Rocks.

In Holyoke, Garjian lifts a roll-up door to a neighboring space, revealing an empty factory building almost a city block in length, with overhead cranes at each end.

“This building was producing wheels for turbines,” he said.

He reckons the space is good for 100 employees.

The company that will produce the CarbonStar system is called E3 LLC, formed with an investor. The company is formalizing a licensing agreement to build the system in New England, Garjian said, and is looking for additional investors.

Garjian noted that measuring and verifying carbon capture is vital when billions of dollars in subsidies, grants, loans and credits are handed out to supposedly carbon-negative technologies.

The Biden administration has pledged hundreds of millions of dollars to carbon management projects.

A life-cycle analysis of his system shows that it sequesters 367 tons of CO2 for every 67 tons it emits, he said.

Garjian is looking at his system as an important tool to combat the warming caused by increasing CO2 emissions.

If emissions aren’t brought under control, he said, “Massachusetts is going to have the climate of South Carolina. In 25 years, we could have a nightmare on our hands.”

Staff Writer James Pentland can be reached at jpentland@gazettenet.com.

Pro-Palestinian encampment disperses at UMass, but protests continue

Pro-Palestinian encampment disperses at UMass, but protests continue Amherst council confirms Gabriel Ting as police chief

Amherst council confirms Gabriel Ting as police chief Music key to Northampton’s downtown revival: State’s top economic development leader tours city

Music key to Northampton’s downtown revival: State’s top economic development leader tours city